Since 1996, Trex has pioneered the composite deck industry and is now the world’s largest wood-alternative decking manufacturer. Expanding into fencing, we lead in outdoor innovation with eco-friendly, high-performance products. Originally a Mobil Corporation division, we went public in 1999. Today, our extensive composite fencing range is available in over 29 countries, boasting a leading market share in North American decking and annual sales exceeding $700 million.

Trex is a globally trusted brand, delivering reliable performance from decking to composite fencing.

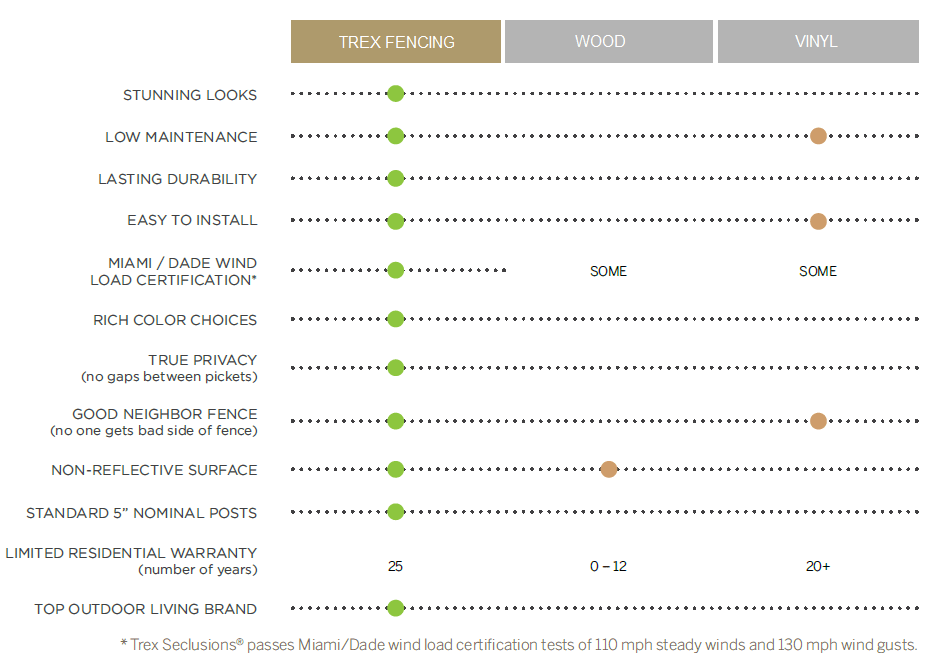

CHOOSING THE RIGHT COMPOSITE FENCE

When it comes to building a long-lasting fence, this cheat sheet helps you choose the right composite fence option. In comparison to wood and vinyl alternatives, including composite fencing and panels, we cover 16 decision points for your backyard and budget. Enjoy the look of wood without the hassle and the convenience of vinyl without sacrificing quality.

Consider options like composite fencing for a durable and aesthetic choice.

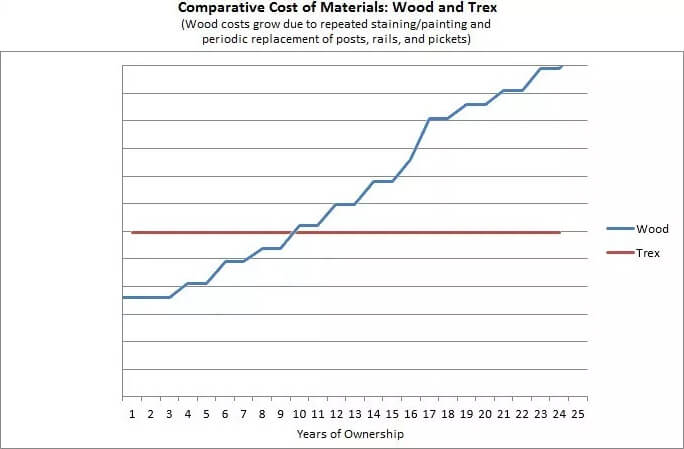

TREX COMPOSITE FENCING COST OF OWNERSHIP COMPARED TO WOOD FENCING

Choosing the right Trex composite fence, including options like composite fencing, composite fence panels, and composite wood fencing, may involve a higher initial expense. However, over time, it proves to be a superior value. About 10-12 years post-installation, the combined expenses of installing and maintaining a basic stockade wood fence surpass the overall investment in a Trex fence.

It’s essential to consider not only the upfront costs but also the long-term benefits. Opting for low-maintenance solutions like composite fence panels means you won’t be spending your weekends on fence upkeep or arranging for maintenance. In the long run, the durability and low-maintenance features of composite fencing, including composite fence panels and composite wood fencing, make it a cost-effective and time-saving choice.

WHY TREX COMPOSITE FENCE PANELS?

So why Trex fencing? We’re committed to helping you create a low-maintenance, high-performance secure backyard retreat. Trex composite fence panels make your life easier by giving your fence the strength of wood fencing without maintenance. Your weekends should be spent relaxing, not repairing your fence.

COMPOSITE FENCING LEADER

Since 1996, Trex has invented, defined, and perfected composite fencing with a lineup of low-maintenance, high-performance products that fundamentally change the way we live outdoors. Trex fencing was introduced in 2005 to meet the demand for a more durable, more natural-looking alternative to vinyl fencing while still meeting the criteria for low maintenance. With Trex composite fencing, you can be at ease in knowing that our well-established brand, backed by its 25-year residential limited warranty, can be trusted to meet the demands for a fence that will last and continue to look attractive for many years.

HOW TO TELL IF IT’S GENUINE TREX COMPOSITE FENCING

The distinct design of Trex fencing immediately catches the eye. Its simulated board-on-board appearance adds character, setting it apart from standard wood fences or vinyl fences. The top and bottom rails are crafted for a visually appealing “picture-frame” effect, complemented by deep, rich colors with a non-reflective matte surface.

Beyond its unique beauty, Trex fence panels stand out as a structurally superior product upon closer inspection. Careful design and testing ensure strength, from reinforced concealed brackets to an engineered aluminum support rail and a unique interlocking picket method. In addition, Trex composite fence panels eliminate the need for internal support like a galvanized steel insert or 4×4 wood post.

GREEN COMPOSITE FENCING

Trex green fencing is an eco-friendly composite made from an innovative blend of 96% recycled wood and plastic. Operating sustainably for over 20 years, well ahead of the green trend, we aim to make a positive impact on the environment. As a leading U.S. plastic recycler, Trex prevents 400 million pounds of plastic and wood from reaching landfills annually. Not only does our eco-friendly composite fencing contribute to a healthier environment, but it also earns LEED points, adding to your good karma. Learn more about Trex and the U.S. Green Building Council’s LEED Rating System.

RECYCLED WOOD

Reclaimed wood that would otherwise end up in a landfill finds its way into Trex high-performance composite materials. By using reclaimed sawdust, we never have had to cut down a tree to make our products. Ever.

RECYCLED PLASTIC

The recycled wood in our composite fences is combined with recycled plastic from a variety of sources ranging from the overwrap on paper towels to dry cleaner bags, sandwich bags, newspaper sleeves, and grocery and shopping bags. The average 100-linear foot Trex composite fence contains 140,000 recycled plastic bags!

ECO-FRIENDLY MANUFACTURING

Trex’s proprietary, eco-friendly processing method eliminates the use of smoke stacks. Also, our factory runoff and refuse are recycled back into the manufacturing line. Our trailers even run on vegetable-based oil hydraulics.

THE BIG PICTURE

Trex works along with other U.S. Green Building Council members to transform the way buildings and communities are designed, built, and operated with the goal of creating environmentally and socially responsible spaces that improve the quality of life.

COMPOSITE FENCE COLORS

Personal aesthetics are an important element in deciding the color of your Trex fence. Consider carefully which color best matches your sensibilities. Here are some examples and ideas for color selection.

SADDLE

Saddle fencing fades from a dark tan to a light tan. It is popular on properties that emphasize earth tones or is used to resemble a natural stain of a wood fence.

WINCHESTER GREY

Winchester Grey fencing starts with a brownish/green hue, transitioning to its intended light grey over time. Initially resembling Woodland Brown, it pairs well with white accents, complements brick or masonry, and adds appeal to modern urban design.

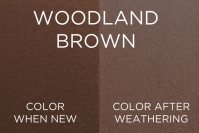

WOODLAND BROWN

Woodland Brown is the darkest Trex fencing color. It is a dark brown. Woodland Brown fades the least from its new color. It is often popular as a contrast to lighter colors on the property.

CHARCOAL BLACK

Charcoal Black is Trex’s boldest and most contemporary color. With minimal fading over time, it delivers a striking contrast against lighter surroundings and pairs beautifully with modern architecture and lush landscapes.

COMPOSITE FENCE COLOR WEATHERING

The extent and pace of weathering in Trex Composite Fencing depend on UV exposure, with less sunlight resulting in a slower fade. Expect natural color variations between components due to the composite material’s production process. While Saddle and Winchester Grey may exhibit more noticeable variation, it doesn’t affect the product’s integrity. Trex Fencing deliberately over-pigments during manufacturing to achieve the desired weathered look after the composite fencing fades. Although all colors lighten over time, not all variation disappears. To minimize this, install pickets with similar pigmentation from the same lot code closely together, when feasible.

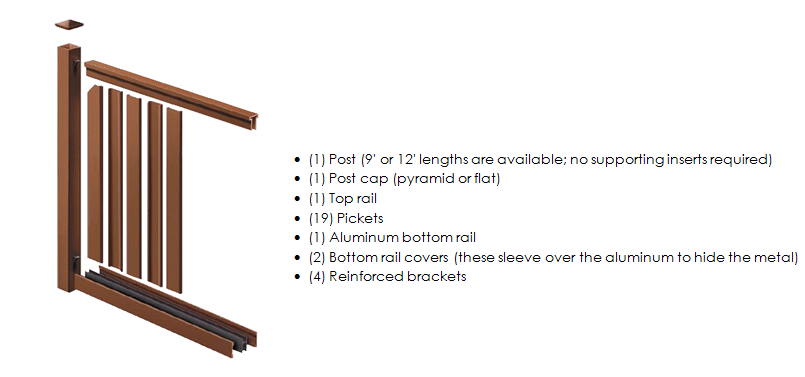

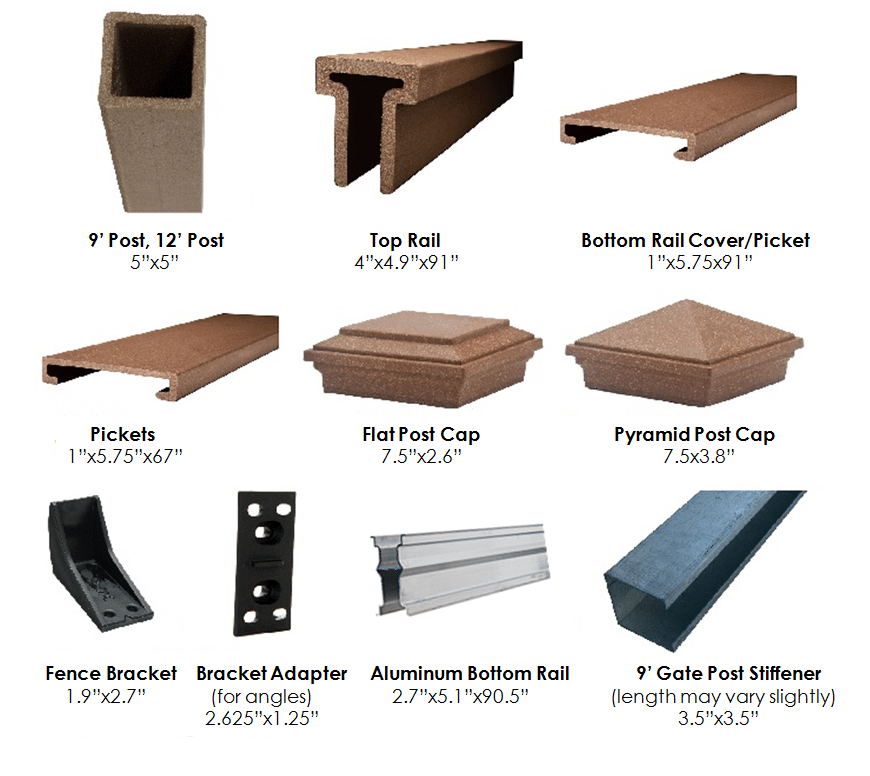

TREX COMPOSITE FENCE COMPONENTS

Trex fencing components include posts, post caps, top rails, bottom rail covers, pickets, aluminum bottom rails, and reinforced fence brackets. The components per 8′ section of fence are:

Posts are commonly set in concrete, and brackets are secured with 1-5/8 in. wood screws, available at local building materials stores. The fence, designed in 8’ sections, can be easily adjusted for shorter lengths by cutting the material. The intelligent design requires only 24 fasteners per section, enabling quick assembly.

Not sure if Trex Composite Fencing is right for you? Curious about the lifetime value of a Trex Composite Fence? Is Trex Composite Fencing a “green” alternative to wood fencing or vinyl fencing? Browse our FAQs to answer your questions.